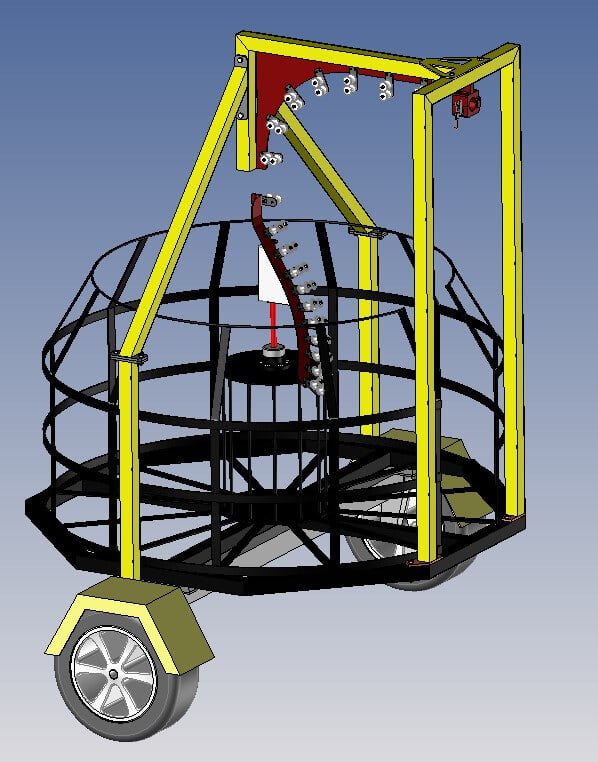

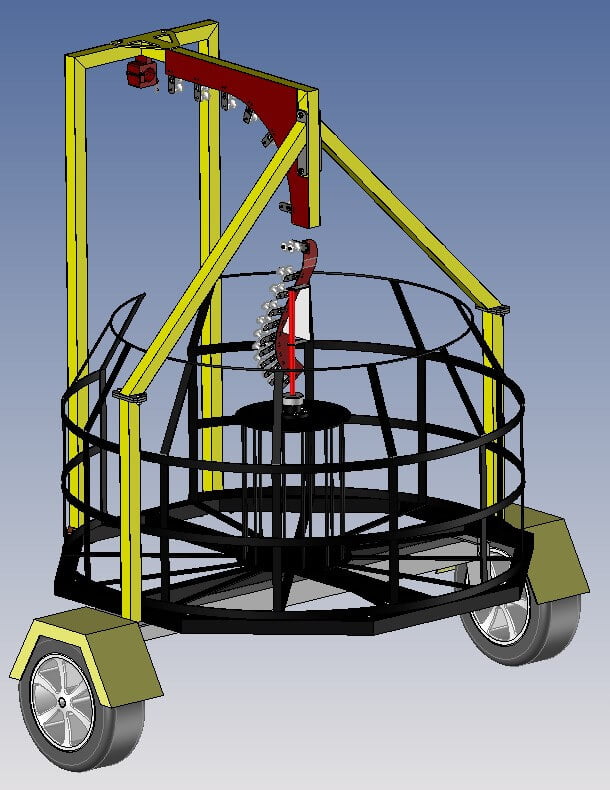

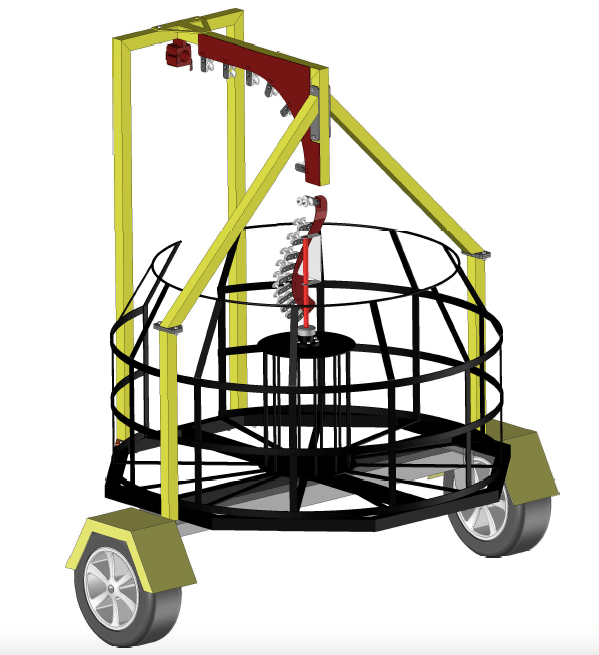

Cable Fleeter Trailer is a trailer-mounted cable storage system used during cable blowing operations to replace manual “figure-eight” cable handling on site. The system temporarily stores the remaining cable after the first duct section is completed and prepares the cable end for the next blowing stage.

By keeping the cable elevated and controlled inside the fleeter cassette, the trailer prevents contamination from mud and dust, reduces bending risk, and improves site safety by eliminating loose cable loops on the ground. This ensures a cleaner cable feed and a smoother transition between multi-leg duct installations.

What is a Cable Fleeter Trailer used for?

- Figure-eight replacement: controlled temporary cable storage without manual looping on the ground

- Multi-leg duct routes: move from leg-1 to leg-2 with cable end ready for the next blowing stage

- Site safety: prevents cable exposure to traffic and reduces trip hazards

- Cable protection: avoids bending abuse and contamination

How it works in cable blowing projects

- Deploy the first leg of the route and pull the remaining cable from the drum.

- Guide the cable into the fleeter cassette via the rotating cable guide quadrant.

- Store the balance of the cable safely inside the fleeter (instead of laying it on the ground).

- Blow the second leg using the same cable end, now clean, protected and organized.

Works alongside a cable blowing machine as part of the overall installation workflow.

Capacity (Typical)

- Cable storage: up to 3,000 m of Ø 13 mm cable (typical)

- Supports drum utilization: up to 6,000 m drum lengths (typical scenario)

Main components

- Road-going trailer chassis

- Cable storage cassette

- Rotating cable guide quadrant

- Duct clamp assembly

- Tension control / brake system (model-dependent)

Advantages

- Faster site operation: less manual handling and fewer cable management mistakes

- Lower risk of cable damage: controlled storage reduces bending and abrasion

- Cleaner cable feed: reduces dirt contamination before blowing

- Safer working area: avoids cable loops on walkways and roads

Safety notes (field basics)

- Keep hands clear of moving guide/quadrant and rollers during operation.

- Secure the trailer and work zone before feeding cable.

- Use PPE according to site rules (helmet, gloves, safety shoes, eye protection).

- Do not exceed rated storage / tension limits.

Request pricing & configuration

Share your cable diameter, planned storage length, and typical jobsite conditions. We will recommend the suitable trailer configuration for your installation workflow.

Email: info@upcom.com.tr