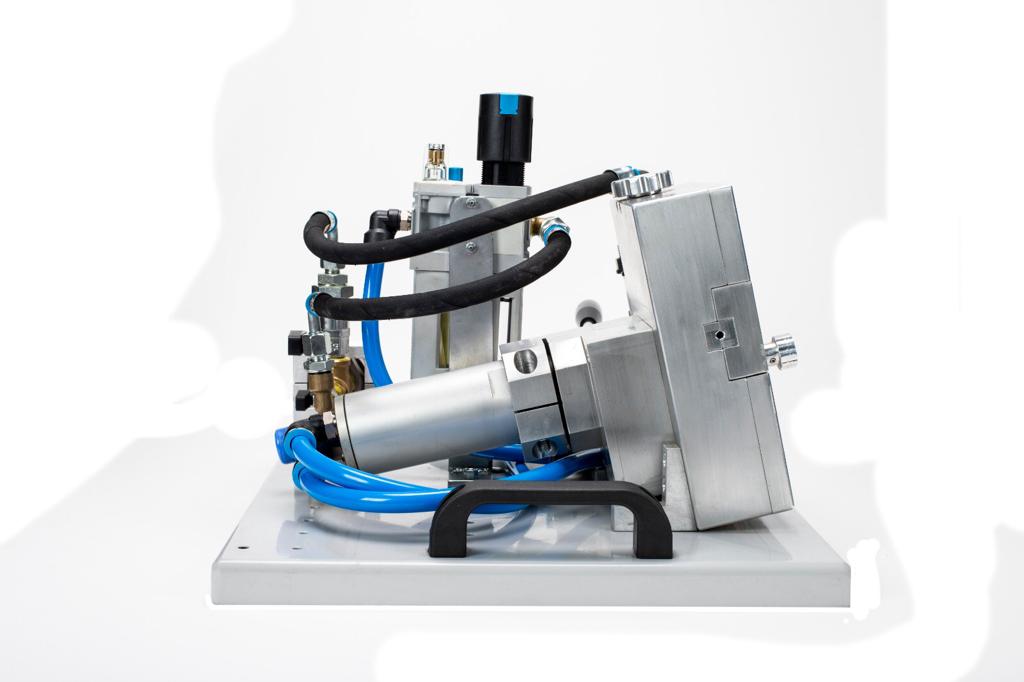

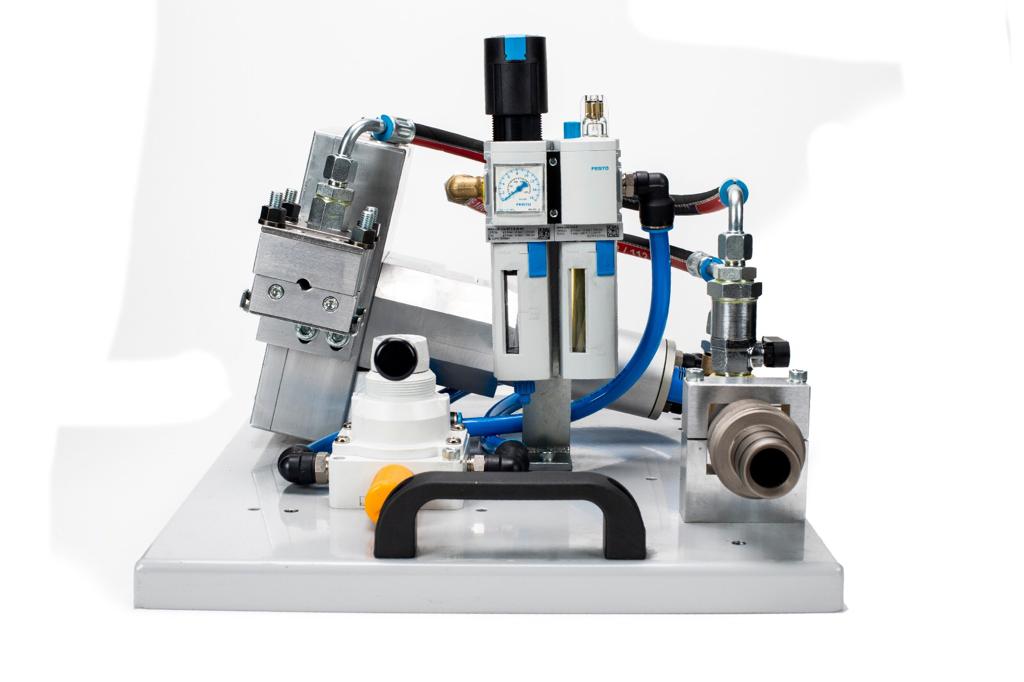

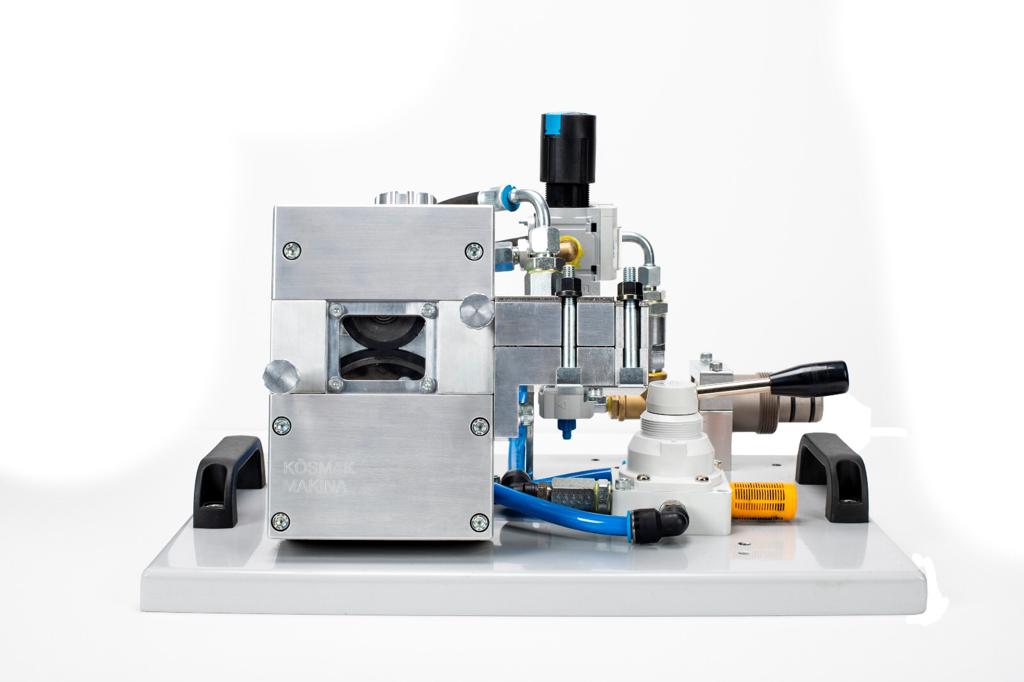

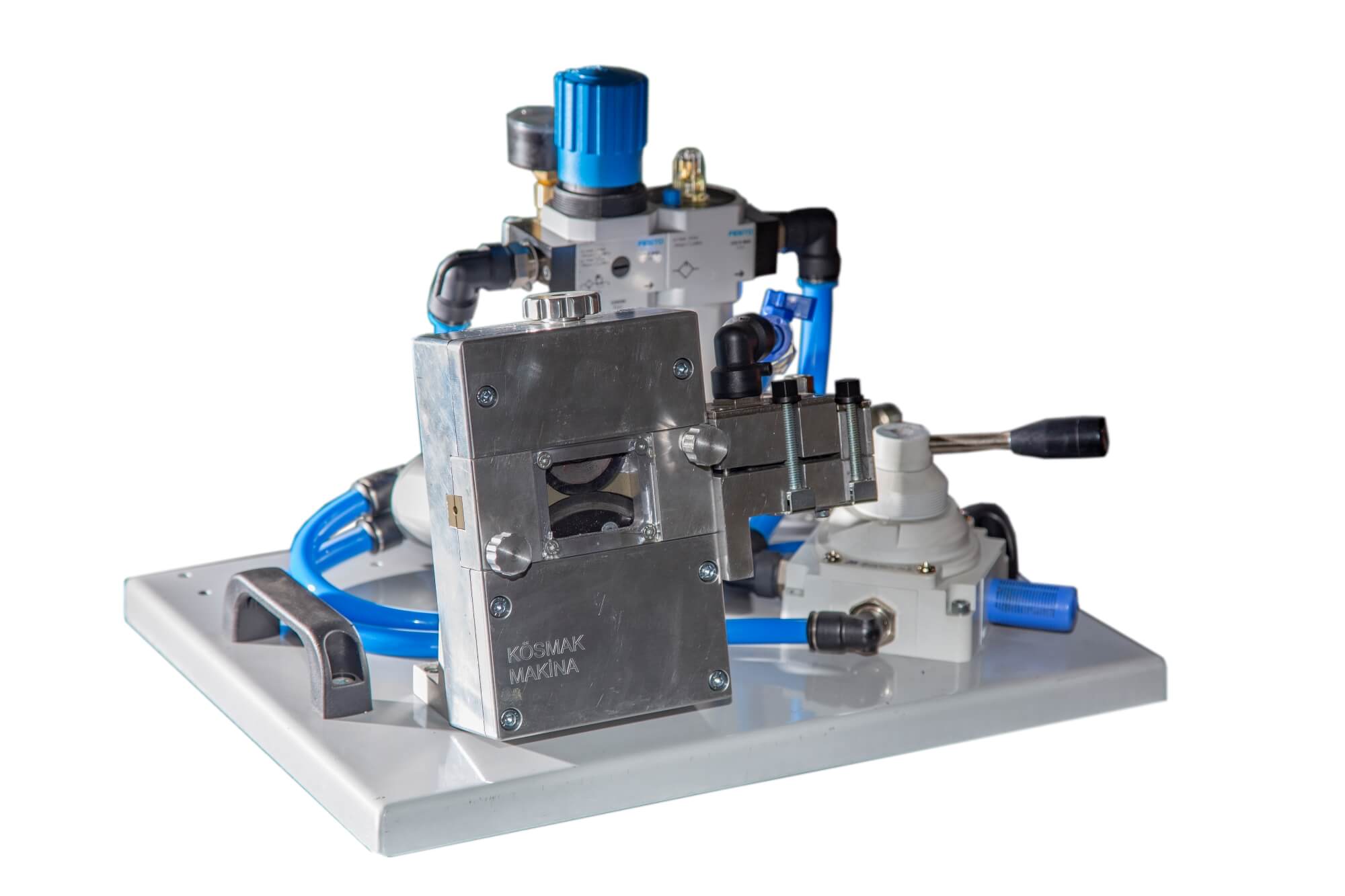

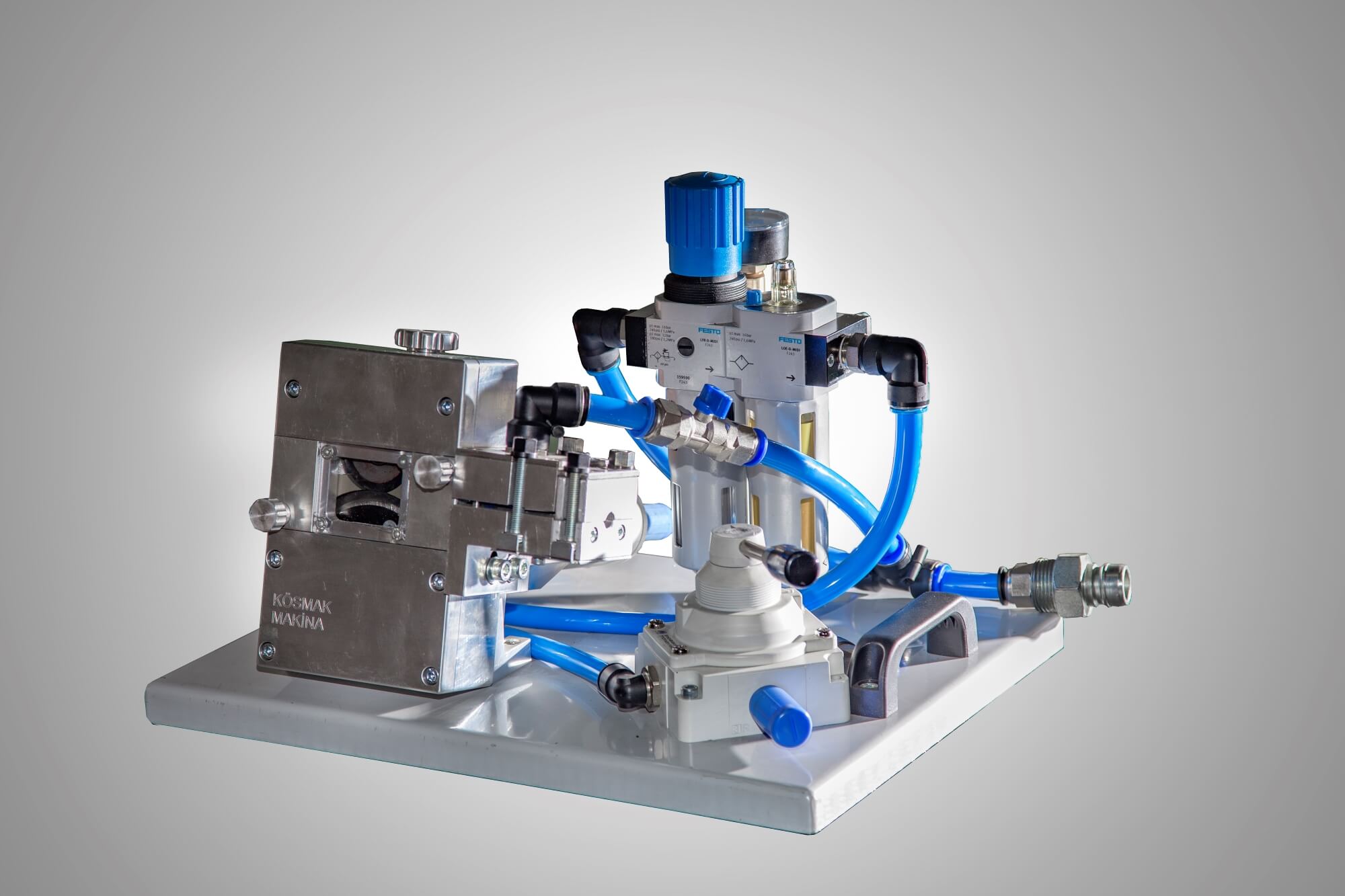

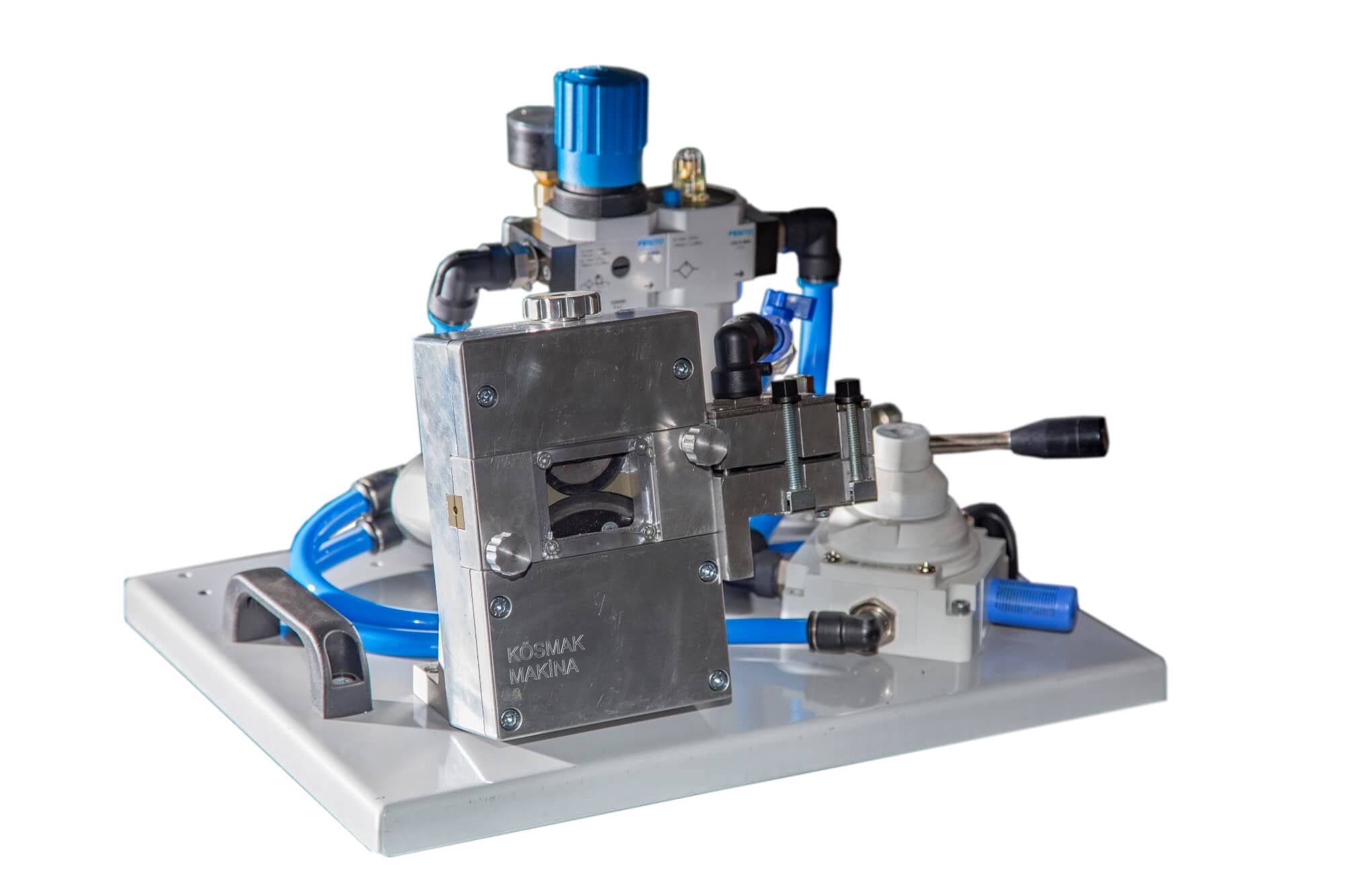

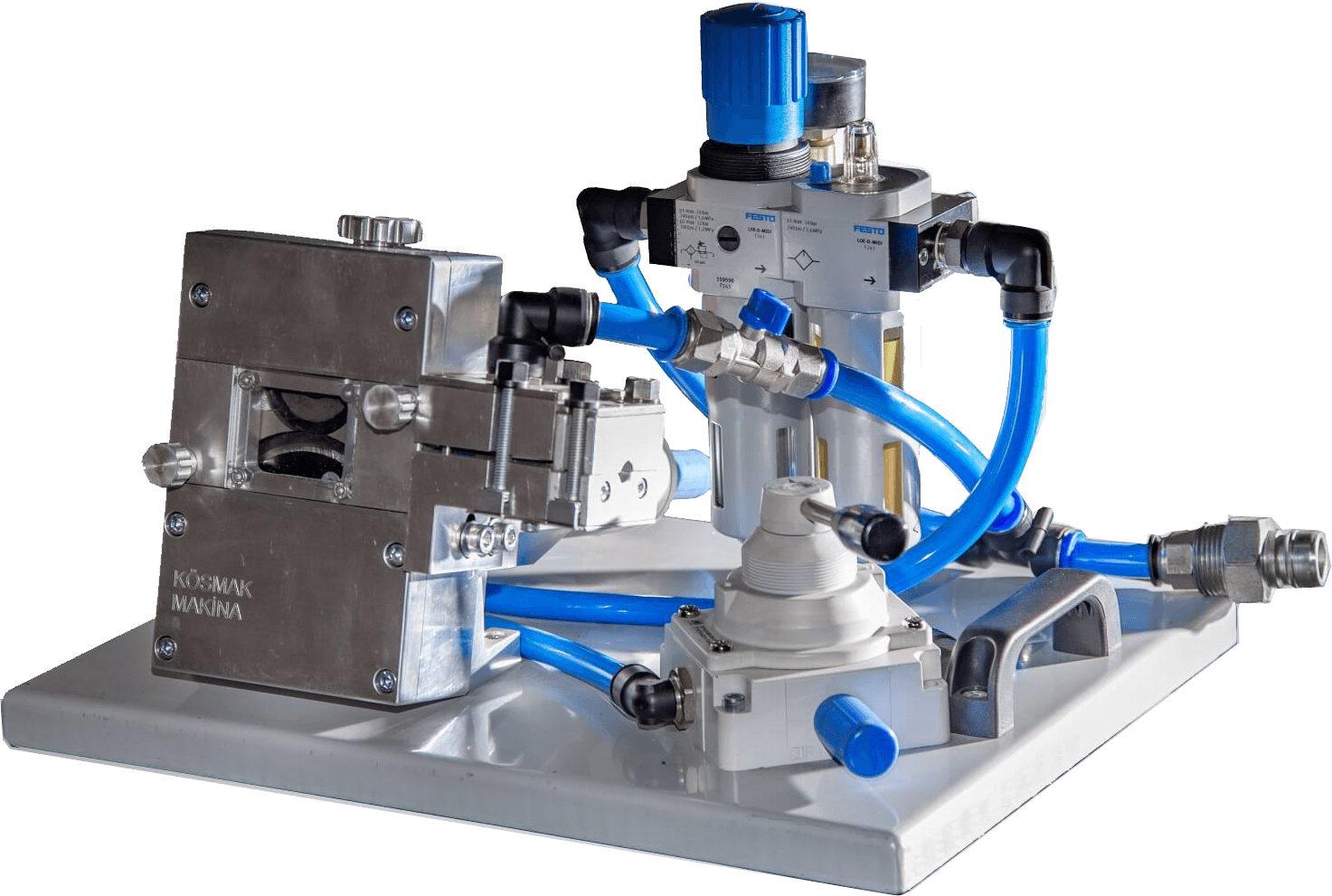

The MikroFOK Cable Blowing Machine is a pneumatic micro-cable installation machine developed for FTTH deployment and microduct infrastructure installation. Its compact structure and pneumatic drive system provide stable cable feeding performance for precision fiber installation projects.

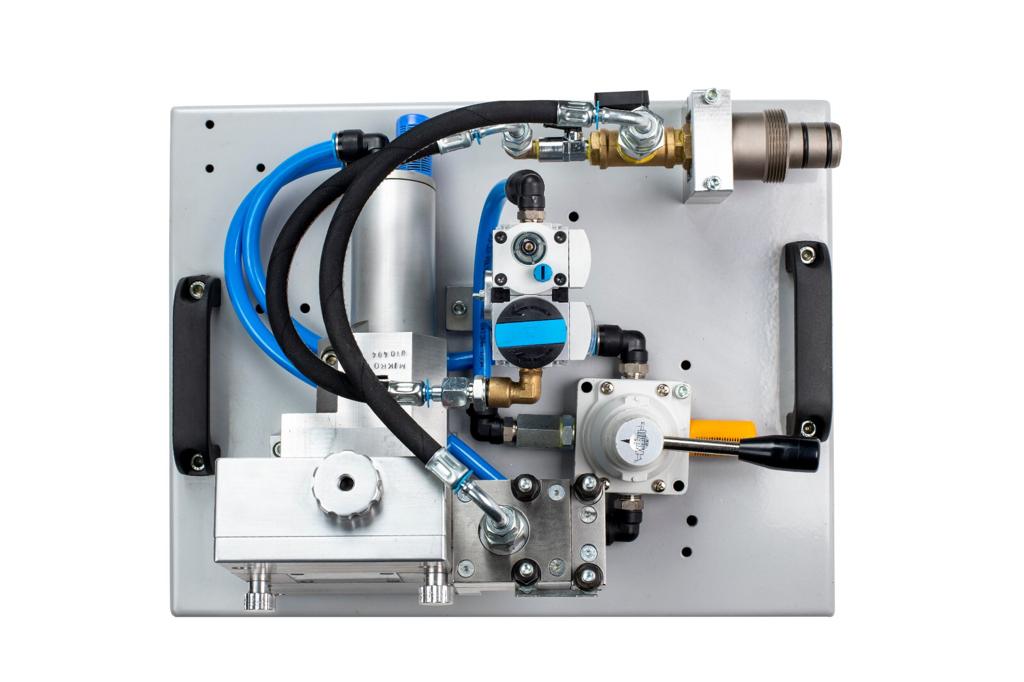

The machine is designed for single-technician operation and allows fast setup in field conditions. Its modular structure enables quick pallet and duct insert changes for different cable and duct diameters.

MikroFOK Cable Blowing Machine Technical Specifications

- Cable diameter: 1–6 mm

- Duct diameter: 6–20 mm

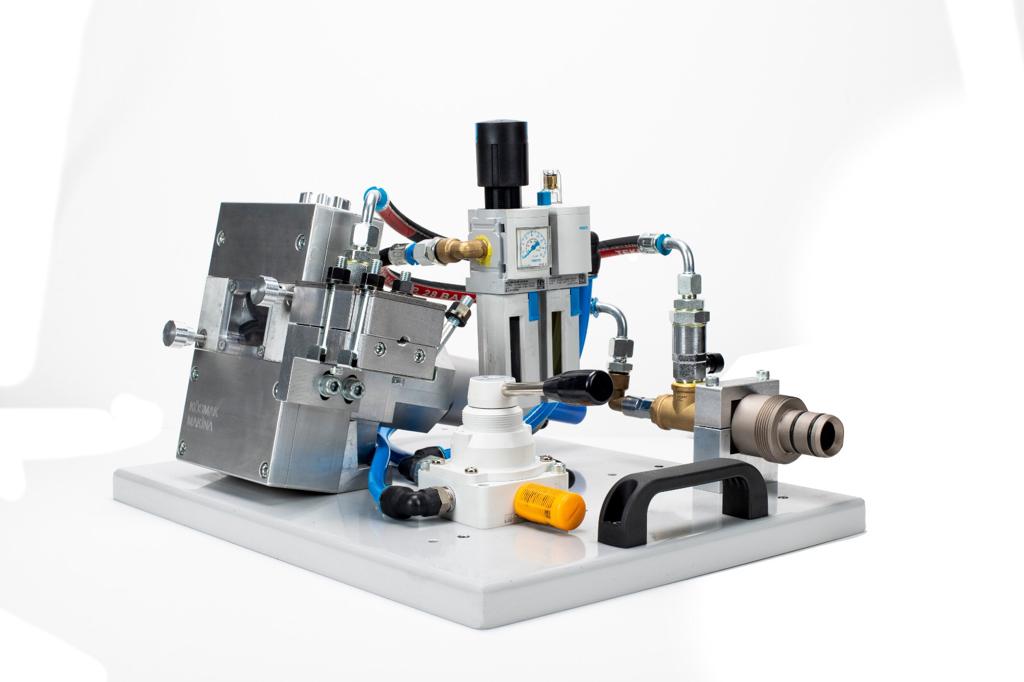

- Drive system: pneumatic motor

- Installation speed: up to 80 m/min

- Direction: forward / reverse

- Dimensions: 350 × 300 × 450 mm

- Weight: 18 kg

Compressor Requirement

- Working pressure: 12 bar

- Air consumption: approx. 1 m³/min

Higher compressor capacity may improve installation performance depending on duct condition, lubrication, and cable type.

Installation Performance

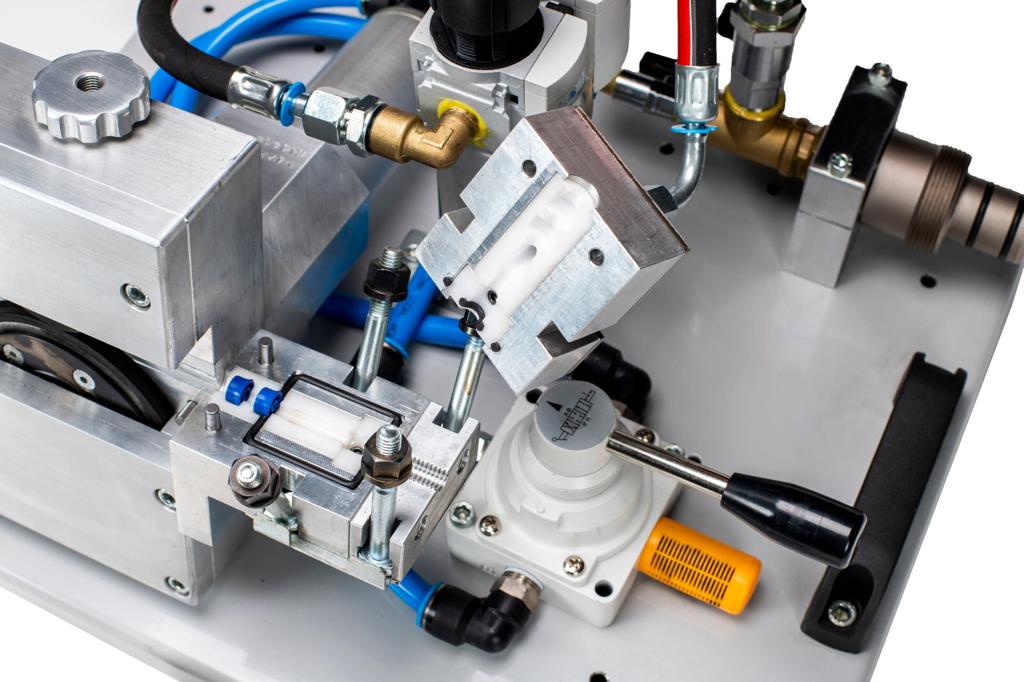

The pneumatic drive system ensures controlled cable feeding while compressed air reduces friction inside the duct. This combined pushing and blowing method allows safe installation of micro fiber cables without excessive mechanical stress.

The MikroFOK machine is commonly used in:

- FTTH last-mile installation

- Microduct fiber deployment

- Urban fiber infrastructure projects

- Indoor fiber installation

- Campus fiber networks

Design Advantages

- Pneumatic contractor-grade drive system

- Single-operator installation capability

- Compact and portable structure

- Quick pallet and duct insert change

- Stable cable feeding control

- Low maintenance mechanical structure

Installation Conditions

Installation performance depends on duct condition, cable stiffness, lubrication quality, and compressor stability. Proper duct preparation and airflow control significantly improve installation distance and cable feeding stability.

Using suitable lubrication and ensuring duct continuity without sharp bends allows the pneumatic drive system to operate efficiently during micro cable installation.

Cable and Duct Compatibility

The MikroFOK Cable Blowing Machine is optimized for micro fiber cables used in FTTH and access network installations. The pallet system ensures stable cable feeding for small-diameter cables while maintaining alignment inside the duct.

Different duct inserts allow the machine to be configured for various microduct diameters, enabling flexible use in different infrastructure projects.

Field Operation Advantages

The compact footprint of the MikroFOK machine allows technicians to operate in narrow installation environments such as manholes, building entrances, and telecom cabinets.

Its pneumatic drive mechanism provides smooth cable feeding while reducing the risk of cable damage during installation. The simple mechanical structure also minimizes maintenance requirements in field operations.

Standards Reference

Fiber cable compatibility reference: ITU-T G.652 fiber optic cable standard .

MikroFOK Cable Blowing Machine – Pallet, Cable Aligning and Duct Options

| Pallet Set (mm) | Cable Aligning Tool (mm) | Duct Connection Tool (mm) |

|---|---|---|

| P1: 3–6 | As required | D8 / D12 / D15 |

Standard delivery includes 1 pallet set + 1 cable aligning tool + 1 duct connection tool.

Ordering Code

Format: MikroFOK - Pallet Set - Cable Aligning Tool - Duct Connection Tool

- Example:

MikroFOK - P1 - C1 - D8 - Multiple ordering example:

MikroFOK - P1+P2+P3 - C1+C2+C3 - D8+D11+D15

If you need a specific duct connection diameter, the duct connection tool can be supplied accordingly.