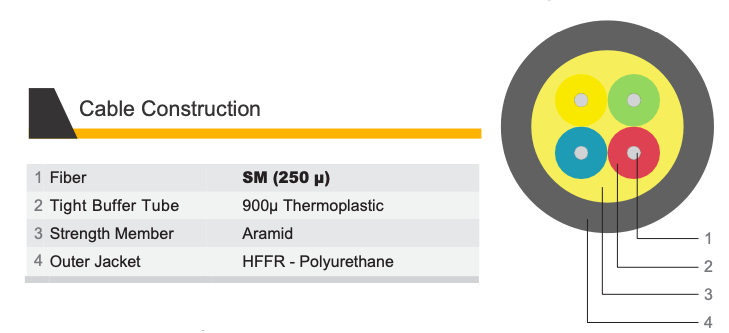

Military Tactical Fiber Optic Cables are rated and ideal for outdoor applications and where extreme environmental conditions are present. They have high flexibility and high crush resistance. Designed to be deployed and retrieved in the field, Military tactical fiber cables are highly well protected to damage caused by repeated impacts crushing forces, abrasion and extreme temperatures. They are made up to 4fibers inside Thermoplastic 900micro Tight buffer Tubes and wrapped with Aramid Yarn. Outer jacket is HFFR – Polyurethane outer jacket. They provide re-deployable audio/video communications and other events in harsh environments. Rugged construction provides superior level of crush resistance. UV Resistant Jacket is ideal for outdoor applications. It has been preferred by military due to its Fast and Robust Field Termination feature. High tensile load capability for excellent termination strength.

Application - Tactical Fiber Cables

- Military Tactical Fiber Cable

- Outside Broadcast

- Security

- Deterrent additive

- Instrumentation and control

- Pipeline and industrial asset monitoring

- Oil and gas

Mechanical and Environmental Properties - Tactical Fiber Cables

| Test | Test Conditions | Value | Unit | Method |

| Tight Diameter | – | 0.9 | mm | – |

| Cable Diameter | – | 5.8 | mm | – |

| Approx. Cable Weight | – | 25 ±2.5 | kg/km | – |

| Max. Tensile Strength | During Installation | 2000 | N | IEC 60794-1-2 E1 |

| In Service | 1500 | |||

| Min. Bending Radius | During Installation | 90 | mm | IEC 60794-1-2 E11 |

| In Service | 60 | |||

| Crush Resistance | ShortTerm | 4000 | ||

| LongTerm | 1000 | N/dm | IEC 60794-1-2 E3 | |

| Impact Resistance | Wp = 2.25 J | 300 | ||

| Flexing | r=80mm , 15N | 20000 | cycles | IEC 60794-1-2 E6 |

| r=40mm, 15N | 1000 | |||

| Repeated Bending | r=40mm , weight =1 kg | 20000 | – | IEC 60794-1-2 E6 |

| Temperature Range | During installation | -40 to +85 | °C | IEC 60794-1-22 F1 |

| In service | -40 to +75 |

Features and Benefits - Tactical Fiber Cables

- Strain relieved with Aramid yarn

- Superior abrasion and cut resistance

- For direct connector assembly

- Ripcord for easy jacket removal

- High chemical protection against acids and alkalies

- For high mechanical and thermal stability

- Improved crush resistance

- Metal free

- Performance high temperature ranges