10 Dec Fiber Blowing Best Practices

Fiber Blowing Best Practices

Why Engineering Quality Determines Fiber Blowing Success - Fiber Blowing Best Practices

In real deployments, 20–30% performance loss comes not from the fiber itself, but from technical misconfigurations: poor duct preparation, incorrect fill ratio, low airflow, wrong lubrication, or ignoring bending/tensile limits.

Optimizing installation parameters increases blowing distance, reduces friction, prevents microbending, and protects the fibers during installation.

Checklist for Comprehensive Fiber Blowing Best Practices

This Fiber Blowing Best Practices checklist applies to modern cable blowing machines used in FTTH, FTTB, backbone, and long-distance network deployments.

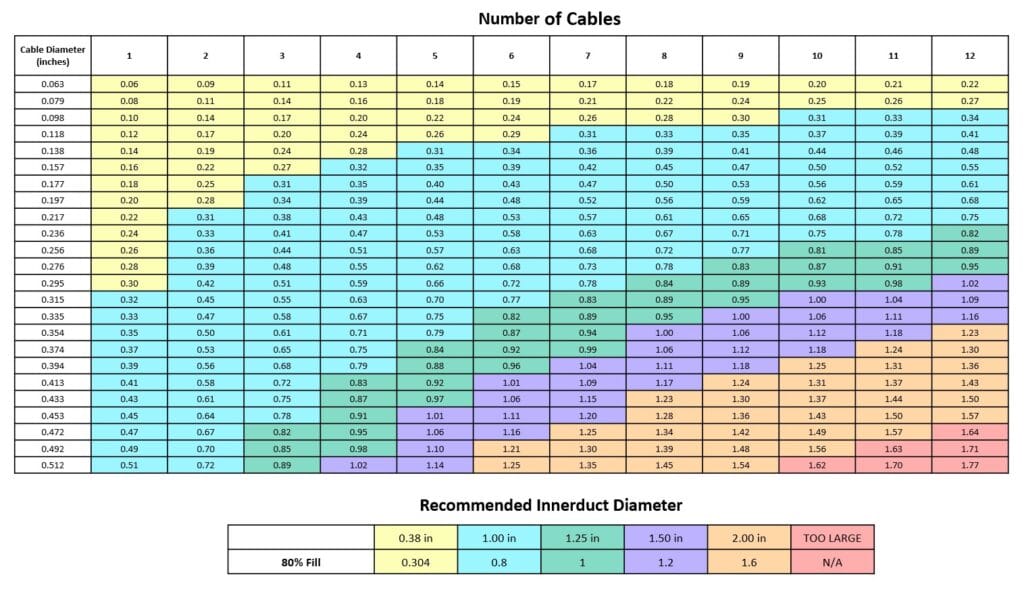

1. Cable & Duct Compatibility

- Cable–duct fill ratio maintained at 40–60%

- Duct inner surface checked (clean, dry, debris-free)

- No ovalization or damage on duct entry

- No tight bends in the first 3–5 meters

- Correct duct diameter selected for the cable outer diameter

This fiber blowing engineering checklist helps installation teams optimize airflow, duct preparation, lubrication strategy, and mechanical limits before starting fiber optic cable blowing operations.

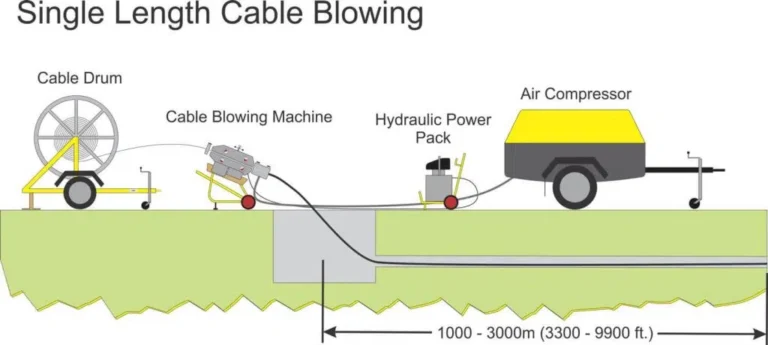

2. Air & Machine Setup

- Compressor airflow capacity verified: 200–600 L/min

- Air filtration and moisture traps active

- Machine rollers/wheels/belts inspected for wear

- Jetting head aligned perfectly with duct entry

- Air pressure test completed before insertion

- All safety stops and emergency controls tested

3. Lubrication Strategy

- Lubricant compatible with dry-core or gel-filled designs

-

Lubrication applied continuously (not in a single spot)

-

Pre-lubrication done for long routes or old ducts

-

Avoid over-lubrication, which can cause oscillation

For long-distance installations, using the correct cable blowing lubricant is critical. You can explore UPCOM cable blowing lubricants below:

4. Mechanical Limits - Fiber Blowing Best Practices

- Tensile rating checked from the manufacturer datasheet

- Crush rating matches expected duct route pressure

- Minimum bending radius respected along entire route

- Installation speed kept within acceptable range

- Drum handling done without additional tension

5. Environmental Conditions - Fiber Blowing Best Practices

- Temperature suitable for jetting (extreme heat increases friction)

- Humidity or condensation inside ducts eliminated

- Duct route scanned for blockages or deformations

- Avoid blowing during rain if ducts are not fully sealed

Here is the UPCOM air Cooler that helps you on your cable jetting blowing application

6. Pre-Start Procedures - Fiber Blowing Best Practices

- Drum positioned to eliminate back tension

- Drum brake calibrated for smooth rotation

- Field team communication established

- Test blowing done for the first 100–200 meters

- Airflow and pressure monitored during test

7. Post-Blowing Procedures

- Fiber end inspected for integrity

- Excess fiber length managed according to project requirements

- Full route documented for future maintenance

- Machine counters reset and logged

Why Engineering Parameters Matter More Than Cable Price - Fiber Blowing Best Practices

Lowering fiber cost rarely improves project performance.

Optimizing engineering parameters consistently delivers:

- Longer blowing distances

- Lower installation time

- Reduced risk of fiber damage

- Higher network lifetime performance

Smart engineering beats cheap materials. Every time. Fiber Blowing Best Practices help you to improve your blowing skills and know-how..

Sources:

ITU-T G.652 Standard:

https://www.itu.int/rec/T-REC-G.652

IEC Optical Fiber Standards:

https://www.iec.ch/technical-committees

FTTH Council Europe Guidelines:

https://www.ftthcouncil.eu/