10 Dec Fiber Optic Distributor Guide: Importing & Supplier Evaluation

For distributors entering the fiber-optic market, choosing the right supplier is not only a commercial decision but a technical one. Optical cables, blowing machines, and related passive components require strict engineering discipline, controlled production parameters, and compliance with international standards.

Working with a trusted supplier ensures consistency, predictable performance, and a stable long-term supply chain.

As a company engineering and manufacturing fiber-optic products and cable-blowing technologies, we see distributors face the same problems repeatedly when sourcing from suppliers with limited technical depth or weak quality control. This fiber optic distributor guide explains the key technical and compliance criteria distributors must evaluate before importing fiber-optic products.

For deployment context and typical network architectures, see: Fiber to the Home (FTTH) deployment guide. For CPR requirements in EU construction works, see: CPR for cables and CPR compliant cables.

Quick Checklist for Distributors

- Ask for traceable test data (optical + mechanical) and batch documentation

- Validate IEC 60794 mechanical performance and installation limits

- Confirm CPR / CE / DoP readiness if selling into the EU

- Check blowing compatibility (sheath friction, stiffness, duct geometry)

- Inspect drum quality + export packaging (meter marking, moisture protection, palletizing)

1. Understanding Manufacturer-Level Engineering Control

- Technically oriented suppliers bring structured engineering discipline to product development. This includes:

- Fiber type selection: G.652.D, G.657.A1/A2, OM3, OM4

- Compound & material behavior under mechanical and thermal stress

- Geometry control: concentricity, ovality, sheath thickness

- Water-blocking design: dry yarn, SWR tape, gel-filled

- Blowing performance parameters: stiffness, friction coefficient

- CPR design compliance for B2ca / Cca / Dca classes

A supplier with manufacturer-level engineering capabilities can explain why each configuration is selected and how it impacts performance in ducts, microducts, aerial routes, or indoor pathways.

2. Optical Fiber Origin and Certification Transparency

Regardless of whether a supplier produces in-house or integrates multiple technical processes, transparency is key. Distributors should request:

- Fiber origin (Sumitomo, Fujikura, Taihan, Draka, etc.)

- ITU compliance

- Factory test results (attenuation, proof test, geometry)

- Batch traceability

Engineering-oriented suppliers maintain documentation that aligns with international standards. You can review our fiber optic cable range here: Fiber Optic Cables.

3. Mechanical Performance Standards Matter

High-quality cables follow mechanical parameters defined by IEC 60794. These values directly influence installation success:

- Tensile performance during pulling or blowing

- Crush resistance for underground or duct applications

- Impact resistance

- Minimum bending radius

- Temperature cycling behavior

Suppliers with manufacturing-level QA processes can provide consistent mechanical data and explain how it is achieved.

4. Fiber Blowing Performance and Duct Compatibility

Fiber blowing is now standard across FTTH, OSP, and backbone installations. Performance depends on:

- Cable stiffness and flexibility

- Surface friction of the sheath

- Geometry tolerance

- Microduct dimensional accuracy

- Lubrication compatibility

Engineering-focused suppliers optimize these parameters during product design to ensure stable blowing distances and predictable installation behavior. For the installation principle, see: Cable blowing by pressurized air.

5. CPR, CE & Global Compliance

For European markets, CPR compliance under EN 50575 is critical. Distributors should verify:

- CPR class (B2ca, Cca, Dca, Eca)

- Notified Body reports

- CE conformity

- IEC 60794 test compliance

- RoHS & REACH documentation

Suppliers with manufacturing-level processes maintain permanent production control (FPC) and issue structured Declarations of Performance. For practical references: CPR for cables and CPR compliant cables.

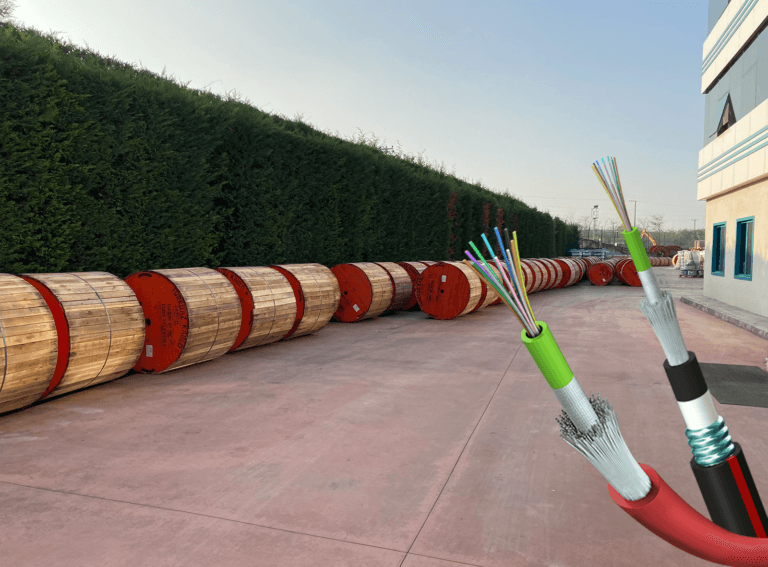

6. Export Packaging, Drum Quality, and Handling Standards

Even when the cable is technically correct, poor packaging causes operational issues. Professional suppliers provide:

- Reinforced wooden drums

- Moisture-resistant wrapping

- Accurate meter marking

- Batch and OFM tracking

- Strong palletizing for export

These procedures reflect a manufacturing-oriented workflow and reduce claims, returns, and installation delays.

7. Technical Support and Engineering Transparency

Distributors benefit when their supplier offers engineering-grade assistance:

- Datasheets prepared by technical teams

- BOM details

- Blowing performance simulations

- Material specifications

- On-site or remote technical support

- Application guidance for FTTH, backbone, microduct, aerial, etc.

This level of support usually comes from suppliers with deep technical involvement and strong production discipline.

8. Total Value Over Lowest Cost

The right partner is not necessarily the cheapest. What matters is whether the supplier can consistently deliver:

- Reliable technical performance

- Documented compliance

- Stable mechanical and optical properties

- Predictable blowing results

- Reduced installation risk for distributors and end users

A technically strong supplier reduces warranty exposure, improves project success rates, and protects the distributor’s reputation in the market.

Related topics for distributors

- FTTH deployment guide

- Cable blowing by pressurized air

- CPR for cables

- CPR compliant cables

- Server cabinet security

Sources: