10 Oct Construction Products Regulation (CPR) for Cables

CPR for cables (Construction Products Regulation) for cables became a legal requirement in July 2017. CPR for fiber optic cables is having an intended use for permanent installation in buildings and construction works, to be accompanied by a Declaration of Performance (DoP). This requirement relates only to the Reaction to Fire performance of Fiber Optic, Data Lan Cables, Power Cables, etc.. As part of CPR for cables, all copper and fiber cables sold into the EU market must comply and hold the CE mark on it. Every CPR product also requires a Declaration of Performance (DoP) from the manufacturer that identifies the product, it is intended use and its Euroclass characteristics.

EN 50575 enables designers and installers to consider the contribution that cables make to the spread of fire. As cables run between rooms and floors or above ceilings and are often made from flammable materials. it’s important that the fire risk can be assessed easily. They can also be a source of ignition if badly installed, damaged or faulty.

CPR Construction products regulation for cables

How will it affect you..

Manufacturers need to draw up a Declaration of Performance (DoP), in a standard format which must include:

- A unique ID for the specific product

- Intended uses

- Manufacturers information

- The AVCP (Assessment and Verification of Constancy of Performance) system applied

- A dated reference of the harmonized standard

- The Notified Body used

- The Declared Performance (or NPD if no performance is declared)

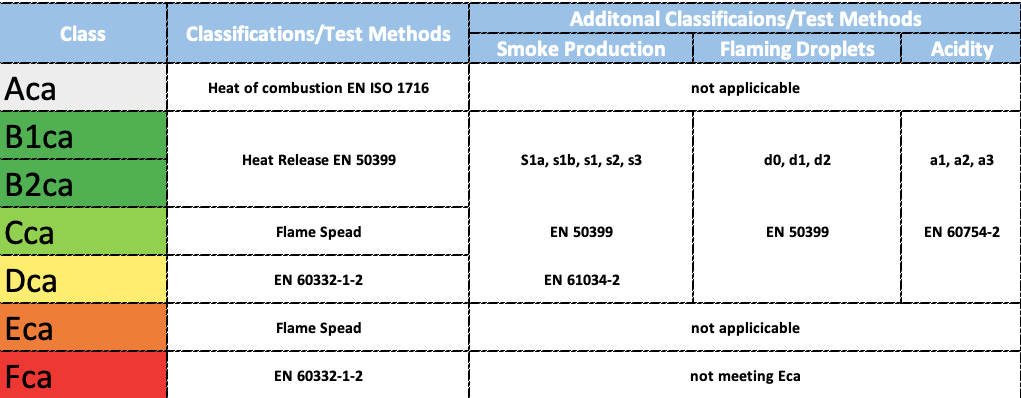

Which fire classes are specified in the standards under the CPR?

CPR en 50575

Preparation Purpose of EN 50575 Standard:

It is the limitation of the formation and spread of fire and smoke, the fire reaction performance and test methods required by the cables within the scope of the standard, such as power, control and communication cables, which are used in general applications in construction works and are subject to fire reaction conditions.

Civil works: Describes all building works including both building and other civil engineering works.

Building material: It describes all materials or tool materials that are produced and put on the market for permanent use in all kinds of construction works or any part of these works, whose performance affects the performance of building works related to basic requirements.

That is, the EN 50575 standard covers all cables manufactured for permanent use in construction and other engineering works.

What cables are not excluded by the CPR?

In the case of cables, whose standard application is developed in EN 50575, CPR Construction products regulation for cables affects only those power cables, telecommunications, data and control, to be incorporated in construction works permanently, whether buildings or works civil engineering. They are excluded those cables for connecting devices such us cables in the automotive sector, electrical cables, etc, in the same way, lift cables and those manufactured for a specific process are not included.

For instance;

• Patch cables (patch cords)

• Cable systems covered by the Machinery Directive (e.g. lift cables)

• Cables not intended for use in construction works (e.g. outdoor cables)

• Flexible cables to devices, lights or machines

• Cables leading to consumers via connectors

• Safety cables with insulation integrity and/or functional integrity

What about our cables and CPR certification?

We are manufacturing an extensive range of EN50575 CPR compliant cables. This range is intended to be used in applications where CPR classification is required. We produce the safest possible cable solutions.

The Construction Products Regulation (CPR) is an EU regulation for installation cables, classifying cables based on their fire performance. It is aimed to improve fire safety in buildings. In case of a fire, the biggest danger is the toxic smoke. Since buildings are filled with cabling, the risk of spreading fire is big.

Our cable range consists of

Tight Buffer Cables, Loose Tube Cables,

FTTx Cables, Arial Type Transmission Fiber Optic Cables,

Industrial Fiber Optic Cables. Data Lan Cable (CAT6, CAT6A and CAT7)

These specially designed cables provide optimal, tested safety in every environment. They are tailor-made to minimize any hazardous smoke, burning droplets and acidity in the smoke. The outer jacket is flame retardant, providing optimal resistance to spreading fire and therefore maximizing the overall safety of the construction and building. Available Euroclass types include B2ca, Cca and Dca, Eca.

Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission Rates

Fiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popula…

No comment 0 LikesOptical Fiber

What is optical fiber? We are used to the concept of moving knowledge in numerous ways. A wire cable transports the sounds from our speech into a socket on the wall and is borne by another cabl…

No comment 8 LikesFTTH installation Technologies

FTTH installation technologies Table of Contents Innovative approach to FTTH installation Technologies…1 Infrastructure Sharing…2 Duct sharing in France…2.1 Sewer pipes…2.2 Cle…

No comment 1 LikeWhat is MPO Cable

What is MPO Cable? Executive summary Push On (MPO) Multi-fiber Connectors – Fiber connectors consisting of several optical fibers are multi-fiber push on connectors, or MPOs for short. While des…

No comment 1 LikeIP55 Outdoor Cabinet

We found out that there is no enough information about 19” IP55 Outdoor Cabinet and thus we will investigate it. If you are reading this article, then you are probably planning to make a procurement s…

No comment 2 LikesWhat is Fiber Optic Cable

What is Fiber Optic Cable? A fiber optic cable, also known as an optical fiber cable, is an assembly similar to an electrical cable, but containing one or more optical fibers that are used to c…

No comment 2 Likes19″ Rack Cabinet

What is a 19” Free Standing Rack Cabinet? 19” free standing rack cabinets provide a robust, cost-effective enclosure solution. PDU mounting or connectivity on both the front and rear of the cabinet. T…

No comment 0 LikesHow Much Does Fiber Optic Cabling Installation Cost?

On average, fiber optic cable installation costs $1 to $6 per 30cm depending on the fiber count. It’s very difficult to estimate an exact price for an entire building to be wired, however an exa…

No comment 4 LikesConstruction Products Regulation (CPR) for Cables

CPR for cables (Construction Products Regulation) for cables became a legal requirement in July 2017. CPR for fiber optic cables is having an intended use for permanent installation in buildings and c…

No comment 0 Likes5 Fan Facts About the Fiber Optic Cables

Fiber optic cables are a type of cable that use glass or plastic fibers to transmit data. Here are some interesting facts about fiber optic cables: Speed: Fiber optic cables are capable of transmittin…

No comment 4 Likes

- Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission RatesFiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,…

- The Benefits and Advantages of Fiber Optic Cables for High-Speed Data TransmissionIntroduction In today’s fast-paced world, the need for high-speed data transmission has become increasingly important. From telecommunication companies to data centers and even homes, everyone requires reliable and fast data transmission. This is where fiber optic cables come in as the preferred method of transmitting…

- Tight-Buffered and Loose-Tube CablesThe difference between tight-buffered and loose-tube fiber optic cables is in the way the fibers are protected and packaged within the cable. Tight-buffered fiber optic cables feature fibers that are surrounded by a tight-fitting buffer material, such as a plastic coating, to protect them from…

- OS1 and OS2 Fiber Optic CoresOS1 OS2 Fiber Cores are types of single mode fiber optic cables that are used for high-speed data transmission. OS1, or “single-mode,” cable has a small core (typically 9 microns in diameter) that allows for a single light beam to be transmitted over long distances…

- Fiber to the home (FTTH)Fiber to the home (FTTH) is a technology that uses optical fibers to deliver high-speed internet and other communication services directly to individual homes or buildings. The fibers are run from a central location, such as a telephone exchange or data center, to a termination…

- Best Fiber Optic Cabling Installation Practices GuideFiber optic cabling installation is a complex process that requires specialized knowledge and equipment. Here are some best practices for fiber optic cabling installation to ensure a successful and reliable installation: Plan the Installation: Before starting the installation, it is important to plan…

- How Fiber Optic Cables and Internet Affect Our LivesFiber optic cables use light to transmit data, rather than electricity. The cable is made up of a central core of extremely pure glass or plastic, surrounded by layers of protective material. Data is encoded as pulses of light that travel along the core of…

- Cable Blowing LubricantCable blowing lubricants are specially formulated lubricants used to lubricate cables as they are being pulled through conduits or other tight spaces during the installation process. The lubricant is applied to the cables before they are pulled, and it helps to reduce friction and make…

- All about fiber opticsWhat does a fiber optic cable do? A fiber optic cable is a type of cable that uses glass or plastic threads to transmit data. These threads, or fibers, are extremely thin and are surrounded by a protective coating. They are able to transmit data…

- 7 important points to blow fiber optic cable far away7 important points to blow fiber optic cable far away, let’s take a look in deep on important cable blowing tips. Cable blowing is the process of blowing the cables into telecom ducts with the help of pressurized air. When using a cable blowing machine…

No Comments