09 May Cable Blowing Machine work

The basic components of a cable blowing machine include a compressor or pump, a hose, and a blowing head. The compressor or pump generates the high-pressure air or water needed to propel the cable, while the hose is used to guide the cable from the machine to the conduit. The blowing head is the device at the end of the hose that directs the high-pressure air or water onto the cable, propelling it through the conduit.

To use a cable blowing machine, the operator first attaches the cable to the blowing head and feeds it into the conduit. The machine is then turned on, and the high-pressure air or water is used to propel the cable through the conduit. The operator guides the cable as it moves through the conduit, ensuring that it is properly positioned and that there are no kinks or twists in the cable.

Cable blowing machines are typically used in the telecommunications, construction, and utility industries, and are widely used in the installation and maintenance of fiber optic cables and other types of cables. They are useful when installing cables in hard-to-reach areas, such as underground or in tight spaces, and can save time and money on large-scale cable installation projects.

In summary, a cable blowing machine, also known as a jetting machine or fiber optic cable blowing machine, is a device used to blow cables, such as fiber optic cables, into ducts or conduits. It works by using high-pressure air or water to propel the cable through the conduit, allowing for quick and efficient installation. Cable blowing machines are typically used in the telecommunications, construction, and utility industries, and are widely used in the installation and maintenance of fiber optic cables and other types of cables.

———————

How Does A Cable Blowing Machine Work and what is Cable blowing machine also called Jetting machine or fiber optic cable blowing machine. The fiber optic cable blowing machines are engineered and manufactured for deploying and installing the fiber optic cables into ducts (micro-ducts or HDPE telecom ducts) by the help of of pressurized air or compressed air. After that, Cable is put into a motorized cable blower head that is plugged to a duct via a one-way air valve.

The pusher head provides the initial pushing force that drives the cable into duct when air source like compressor is introduced to the duct through the one-way air valve. Then Hydraulic or Pneumatic motors will help to push the cable into ducts and compressed air will decrease the friction of cable by preventing the cable contacting ducts. Therefore, the cable can be pushed through thousands of kilometer of pre-installed duct. Such long distances are possible with the high air drag and low friction generous. So it will be good to use Lubricant Oil. To reduce friction between cable and duct, you can consider to add special lubricant into ducts.

On the other hand it might be good idea to use an Air Cooler for more safe cable blowing.

Air Cooler:

Air Cooler remarkably effects and increases the “blowing” performances and protects the cable from the high temperature with the cooling feature of this accessory when climate temperature exceeds 20°C.

Air Cooler Machine is very much recommended making a safe cable deployment in long distances without or with less friction and this will protect your cable from the potential damages that are mainly high temperature on the cable jacket surface. This heat may cause to melding of cable jacket and cost you high.

Special mechanism of machine changes the high temperature air with the air outside. The pressurized cool air will drive the fan that propels the air outside with low temperature.

This machine should be between the air-compressor and the cable blowing machine, which limits the pressurized air’s temperature up to max around 10°C more than the air in the climate in order to prevent the overheating problems.

Without air cooler, the temperature of compressed air exiting the compressor is around 35°C above the ambient temperature.

In case no air cooler, then the air temperature compressed may exceed the environment temperature by 30 or 35C.. This means that total temperature may go up to 70C. Such a temperature will meld the outer jacket of cable.

Any temperature more than 50°C, will soften the outer sheath of cable and also pre-installed duct walls. Due to aforesaid reasons your cable deployment time and cost will remarkably increase, length of cable you install will be much less. This will bring the risk of bursting of ducts.

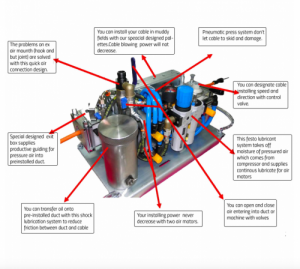

Blowing machine design

Fiber Optic cable blowing machine mainly consists of following parts

- Adjustment and lubrication mechanism

- Mechanical or digital cable meter counter

- Pressurized air plug or connection

- Cable router

- Base line plate or basement

- Pallet and or belt feeder mechanism

- Pushing head

A Fiber cable blowing machine consists of the following components:

- a head that is assuring secure fitting of the duct that we will install the cable inside. It is going to be providing the medium (Air/Pneumatic or Oil/Hydraulic) to the HDPE telecom ducts. Afterwards the fiber cable pushed into the HDPE duct through the head goes inside a sealing system preventing the medium from getting into the machine;

- a pallet or belt feeder which pushes the cable forward the head;

- a basement plate or a frame onto which the cable blowing machine’s subsystems are assembled

- cable router, which is a system of bushes or rolls routing the cable forward the blowing head;

- air or oil supply is ensued to the blowing machine securely;

- a digital or mechanical meter counter which shows the length (in some cases the cable velocity) of the installed cable

- and control unit which helps you to control cable speed blown and the propelling power of the feeder.

Types

Machines are classified with regard to the diameter of the cable they can handle and the type of drive system (track feeder, roller feeder, belt feeder or blower heads without feeders). The machines are of 2 types.

- Hydraulically powered

- Pneumatically powered.

The hydraulically blowing machine consists of 2 parts.

- Cable feeding unit: – This is the main component and it pushes the cable into the HDPE duct with the help of compressed air.

- Hydraulic Power pack: – This unit provides the power to cable feeding unit and it is because of hydraulic power pack, the cable feeding unit operates.

How does a cable blowing machine work?

Latest Posts:

- Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission RatesFiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,…

- The Benefits and Advantages of Fiber Optic Cables for High-Speed Data TransmissionIntroduction In today’s fast-paced world, the need for high-speed data transmission has become increasingly important. From telecommunication companies to data centers and even homes, everyone requires reliable and fast data transmission. This is where fiber optic cables come in as the preferred method of transmitting…

- Tight-Buffered and Loose-Tube CablesThe difference between tight-buffered and loose-tube fiber optic cables is in the way the fibers are protected and packaged within the cable. Tight-buffered fiber optic cables feature fibers that are surrounded by a tight-fitting buffer material, such as a plastic coating, to protect them from…

- OS1 and OS2 Fiber Optic CoresOS1 OS2 Fiber Cores are types of single mode fiber optic cables that are used for high-speed data transmission. OS1, or “single-mode,” cable has a small core (typically 9 microns in diameter) that allows for a single light beam to be transmitted over long distances…

- Fiber to the home (FTTH)Fiber to the home (FTTH) is a technology that uses optical fibers to deliver high-speed internet and other communication services directly to individual homes or buildings. The fibers are run from a central location, such as a telephone exchange or data center, to a termination…

- Best Fiber Optic Cabling Installation Practices GuideFiber optic cabling installation is a complex process that requires specialized knowledge and equipment. Here are some best practices for fiber optic cabling installation to ensure a successful and reliable installation: Plan the Installation: Before starting the installation, it is important to plan…

- How Fiber Optic Cables and Internet Affect Our LivesFiber optic cables use light to transmit data, rather than electricity. The cable is made up of a central core of extremely pure glass or plastic, surrounded by layers of protective material. Data is encoded as pulses of light that travel along the core of…

- Cable Blowing LubricantCable blowing lubricants are specially formulated lubricants used to lubricate cables as they are being pulled through conduits or other tight spaces during the installation process. The lubricant is applied to the cables before they are pulled, and it helps to reduce friction and make…

- All about fiber opticsWhat does a fiber optic cable do? A fiber optic cable is a type of cable that uses glass or plastic threads to transmit data. These threads, or fibers, are extremely thin and are surrounded by a protective coating. They are able to transmit data…

- 7 important points to blow fiber optic cable far away7 important points to blow fiber optic cable far away, let’s take a look in deep on important cable blowing tips. Cable blowing is the process of blowing the cables into telecom ducts with the help of pressurized air. When using a cable blowing machine…

No Comments