09 Jan What is Fiber Optic Cable

What is Fiber Optic Cable? A fiber optic cable, also known as an optical fiber cable, is an assembly similar to an electrical cable, but containing one or more optical fibers that are used to carry light. The optical fiber elements are typically individually coated with plastic layers and contained in a protective tube suitable for the environment where the cable will be deployed. (1)

First commercially deployed in 1977, optical cable is the primary source of long-distance, high-bandwidth communications between telephone companies, multisite organizations and various other long-range communications applications. The composition of optical cable starts with the outer jacket, which is made of a strong and often flexible material. This is followed by plastic cover used to bundle individual optical fiber cables. An optical fiber typically consists of a transparent core surrounded by a transparent cladding material with a lower index of refraction. Light is kept in the core by total internal reflection. Single-wavelength or multiple-wavelength light is passed through the core and keeps traveling inside the core due to the lower refractive index cladding surrounding it, which bounces the light back when it tries to escape.

What is Optical Fiber?

An optical fiber is a flexible, transparent glass/fiber made by drawing glass (silica) or plastic to a diameter slightly thicker than that of a human hair. Transmission is the transfer of a signal as the light pulse along a glass (silica) fiber.

Types

Optical fibers carry light signals down them in what are called modes. Different ways of traveling: a mode is simply the path that a light beam follows down the fiber. One mode is to go straight down the middle of the fiber. Another is to bounce down the fiber at a shallow angle. Other modes involve bouncing down the fiber at other angles, more or less steep.

Single Mode

The simplest type of optical fiber is called single-mode. It has a very thin core about 5-10 microns (millionths of a meter) in diameter. In a single-mode fiber, all signals travel straight down the middle without bouncing off the edges (yellow line in diagram). Single-mode fibers generally carries the Cable TV, Internet, and telephone signals, wrapped together into a huge bundle. Cables like this can send information over 100 km (60 miles).

Multi Mode

Another type of fiber-optic cable is called multi-mode. Each optical fiber in a multi-mode cable is about 10 times bigger than one in a single-mode cable. This means light beams travels through the core at following a variety of different paths (yellow, orange, blue, and cyan lines)—in other words, in multiple different modes. Multi-mode cables can send information only over relatively short distances and are used (among other things) to link computer networks together.

Even thicker fibers are used in a medical tool called a gastroscope (a type of endoscope), which doctors poke down someone’s throat for detecting illnesses inside their stomach. A gastroscope is a thick fiber-optic cable consisting of many optical fibers. At the top end of a gastroscope, there is an eyepiece and a lamp. The lamp shines its light down one part of the cable into the patient’s stomach. When the light reaches the stomach, it reflects off the stomach walls into a lens at the bottom of the cable. Then it travels back up another part of the cable into the doctor’s eyepiece. Other types of endoscopes work the same way and can be used to inspect different parts of the body. There is also an industrial version of the tool, called a fiberscope, which can be used to examine things like inaccessible pieces of machinery in airplane engines.

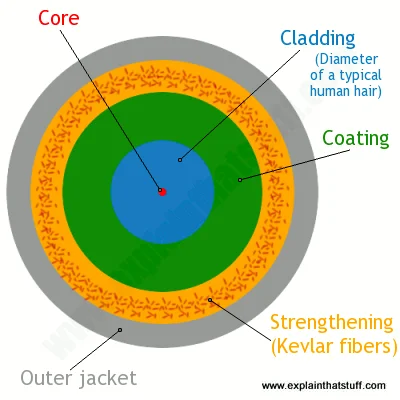

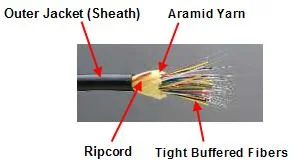

Artworks: Above: Light travels in different ways in single-mode and multi-mode fibers. Below: Inside a typical single-mode fiber cable (not drawn to scale). The thin core is surrounded by cladding roughly ten times bigger in diameter, a plastic outer coating (about twice the diameter of the cladding), some strengthening fibers made of a tough material such as Aramid Yarn with a protective outer jacket on the outside.

Fiber Optic Cables Design

For fiber optic cables to replace the copper cables, they must safely be applied and maintained in all the application and environments where metallic conductor cable are installed and maintained. Due to its fragile structure, Fiber cables must be protected and must have very good mechanical properties to work in these environments such as underground ducts, direct burial or Aerial Application.

However, glass optical fibers themselves are very fragile and very susceptible to mechanical handling and strike.That’s why, the optical fiber glass fibers are wrapped by protective materials including coating and cabling to be able to handle the mechanical impacts and strikes in installation and maintenance.

Due to above mentioned facts, fiber optic cables have four characteristics;

- BUFFER (Optical Fiber)

- STRENGTH MEMBERS

- FIBER CABLE JACKET

- WATER/FLOODING BARRIER

1) BUFFER (Optical Fiber)

In a fiber optic cable, a buffer is one type of component used to encapsulate one or more optical fibers for the purpose of providing such functions as mechanical isolation, protection from physical damage and fiber identification.

Bare glass fibers are composed of core and cladding and both are based on silica or other glass materials.

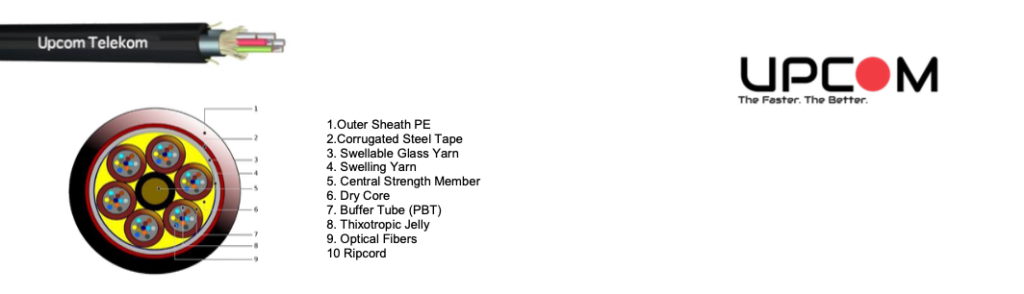

The buffer may take the form of a miniature conduit, contained within the cable and called a “loose buffer(Loose Tube)”, or “Tight Buffer”. A loose or tight buffer may contain more than one fiber, and sometimes contains a lubricating (thixotropic) gel. A “tight buffer” consists of a polymer coating in intimate contact with the primary coating applied to the fiber during production

Loose Tube:

Designed for harsh environmental conditions in the outdoors. In loose tube cables, the coated fiber “floats” within a rugged, abrasion resistant, oversized tube which is filled with optical gel.

Tight Buffer:

Tight buffered cables, in contrast, are optimized for indoor applications. In the tight buffer construction, instead of using the gel layer loose tube cable has, it uses a two-layer coating.

2) STRENGTH MEMBERS

A strength Member is an added component to a jacketed Cable to help protect and strengthen the cable construction. Most of the time it is Aramid Yarn and Glass Yarn, but can also be a flexible, but stiff fiberglass rod that runs the length of the cable. That part of a Fiber Optic Cable composed of aramid yarn, steel strands, or fiberglass filaments that increase the Tensile Strength of the cable.

Structural and strength members can be solid or stranded steel wire, Aramid Yarn or fiber glass. They must have a high Young’s modulus, high strain capability, flexibility and low weight per unit length.

3) FIBER CABLE JACKET

The fiber optic cable cab be surrounded by an outer jacket for reducing the abrasion and the first line of defense against the surrounding environment. This layer of the cable is usually made of plastic based products and called fiber cable jacket or fiber cable sheath. It resists water entry while remaining inert to gases and liquids that the cable may be exposed to during its service life

The fiber cable jacket contains the cable core and has various complexity from one simple extruded plastic jacket to a multilayer structure consisting of two or more jackets and with intermediate armoring.

Types:

PE – Polyethylene (MDPE – medium density PE / HDPE – high density PE)

- Primary outside jacket material.

- Good resistance to UV (sun light) due to carbon black.

- Good flexibility over wide range of temperatures.

- Good abrasion and crack resistance.

PVC – Polyvinyl chloride

- Provides good mechanical protection.

- Flexible at normal installation temperatures.

- Flame retardant.(typical riser material)

- Used for many indoor applications.

- Can be protected against sunlight with various UV inhibitors.

LSZH – Low smoke, zero halogen

- Flame Retardant with low smoke and no halogenated materials

- For use in unventilated areas exposed to public, e.g., subways and tunnels.

- Good mechanical performance.

4) WATER/FLOODING BARRIER

Fibre optic cables are usually installed in non-watertight piping and cable ducts. The fibers need to be effectively protected from humidity and water flooding in order to make sure the operational reliability of the fiber optic cables.

And the plastic sheath material tends to give very limited protection against the penetration of water into the cable.

General water barriers for regular cables are axially laid aluminum foil/polyethylene laminated film immediately inside the polyurethane or polyethylene plastic sheaths; and/or the use of moisture resistant compounds such as Swellable Glass Yarn around the fibers.

Moisture resistant compounds include petroleum jelly and silicone rubber. These filling compounds need to be soft, self-healing, easily removed, provide corrosion protection for metallic cable components and do not degrade over time or harm the other components. These materials have another useful property in cushioning the fibers from vibration.

FIBER OPTIC CABLE SAMPLE

The following is an illustration of a basic fiber optic cable design

Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission Rates

Fiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popula…

No comment 0 LikesOptical Fiber

What is optical fiber? We are used to the concept of moving knowledge in numerous ways. A wire cable transports the sounds from our speech into a socket on the wall and is borne by another cabl…

No comment 8 LikesFTTH installation Technologies

FTTH installation technologies Table of Contents Innovative approach to FTTH installation Technologies…1 Infrastructure Sharing…2 Duct sharing in France…2.1 Sewer pipes…2.2 Cle…

No comment 1 LikeWhat is MPO Cable

What is MPO Cable? Executive summary Push On (MPO) Multi-fiber Connectors – Fiber connectors consisting of several optical fibers are multi-fiber push on connectors, or MPOs for short. While des…

No comment 1 LikeIP55 Outdoor Cabinet

We found out that there is no enough information about 19” IP55 Outdoor Cabinet and thus we will investigate it. If you are reading this article, then you are probably planning to make a procurement s…

No comment 2 LikesWhat is Fiber Optic Cable

What is Fiber Optic Cable? A fiber optic cable, also known as an optical fiber cable, is an assembly similar to an electrical cable, but containing one or more optical fibers that are used to c…

No comment 2 Likes19″ Rack Cabinet

What is a 19” Free Standing Rack Cabinet? 19” free standing rack cabinets provide a robust, cost-effective enclosure solution. PDU mounting or connectivity on both the front and rear of the cabinet. T…

No comment 0 LikesHow Much Does Fiber Optic Cabling Installation Cost?

On average, fiber optic cable installation costs $1 to $6 per 30cm depending on the fiber count. It’s very difficult to estimate an exact price for an entire building to be wired, however an exa…

No comment 4 LikesConstruction Products Regulation (CPR) for Cables

CPR for cables (Construction Products Regulation) for cables became a legal requirement in July 2017. CPR for fiber optic cables is having an intended use for permanent installation in buildings and c…

No comment 0 Likes5 Fan Facts About the Fiber Optic Cables

Fiber optic cables are a type of cable that use glass or plastic fibers to transmit data. Here are some interesting facts about fiber optic cables: Speed: Fiber optic cables are capable of transmittin…

No comment 4 Likes

- Advancements in Fiber Optic Technology: Improving Bandwidth and Transmission RatesFiber optic technology has revolutionized the way we communicate, providing faster and more reliable data transmission over long distances. The use of fiber optic cables has become increasingly popular in recent years, and the technology continues to evolve at a rapid pace. In this article,…

- The Benefits and Advantages of Fiber Optic Cables for High-Speed Data TransmissionIntroduction In today’s fast-paced world, the need for high-speed data transmission has become increasingly important. From telecommunication companies to data centers and even homes, everyone requires reliable and fast data transmission. This is where fiber optic cables come in as the preferred method of transmitting…

- Tight-Buffered and Loose-Tube CablesThe difference between tight-buffered and loose-tube fiber optic cables is in the way the fibers are protected and packaged within the cable. Tight-buffered fiber optic cables feature fibers that are surrounded by a tight-fitting buffer material, such as a plastic coating, to protect them from…

- OS1 and OS2 Fiber Optic CoresOS1 OS2 Fiber Cores are types of single mode fiber optic cables that are used for high-speed data transmission. OS1, or “single-mode,” cable has a small core (typically 9 microns in diameter) that allows for a single light beam to be transmitted over long distances…

- Fiber to the home (FTTH)Fiber to the home (FTTH) is a technology that uses optical fibers to deliver high-speed internet and other communication services directly to individual homes or buildings. The fibers are run from a central location, such as a telephone exchange or data center, to a termination…

Sorry, the comment form is closed at this time.